South Burlington Municipal Eco Machine

South Burlington Municipal Eco-Machine

South Burlington, Vt.

Built with a grant from the US Environmental Protection Agency, the South Burlington Eco-Machine demonstrated high performance even in very cold temperatures. On a daily basis the sewage typically generated by 1,200 residents at 80,000 gallons was diverted from the city’s conventional waste treatment plant to the Eco Machine. The South Burlington Eco-Machine was built in late 1995 by Living Technologies Inc. and Dr. John Todd with Ocean Arks International undertaking scientific oversight.

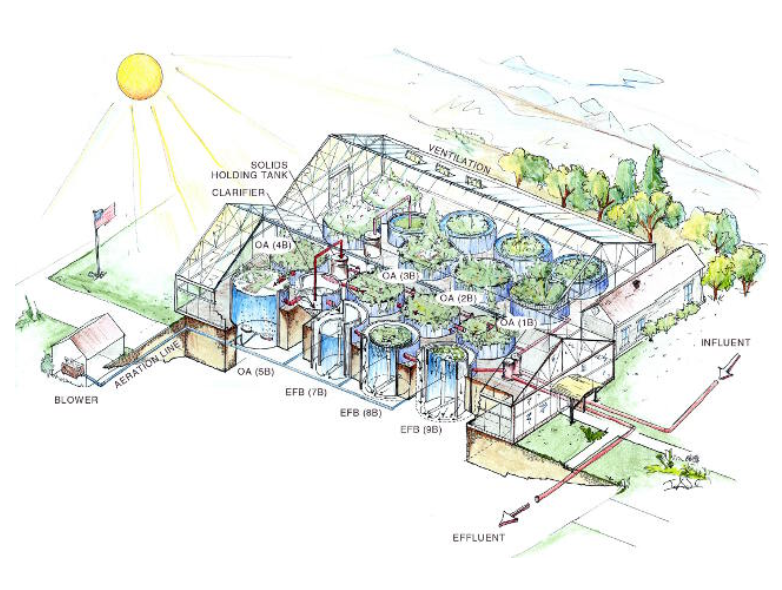

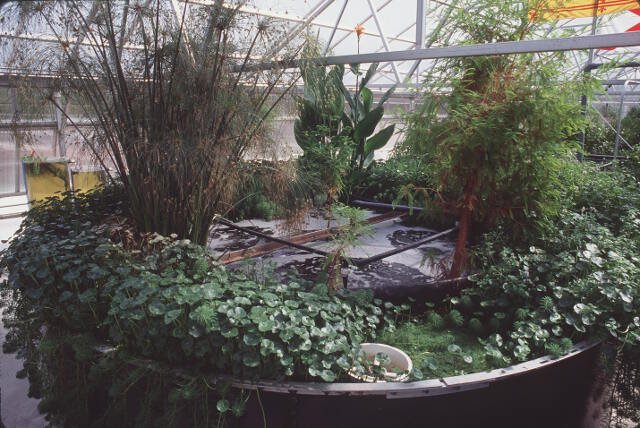

Inside the greenhouse, the system used several stages to achieve stable nutrient removal. First, sewage flowed through aerobic reactors made of aerators and a variety of plants. In this environment lived a host of organisms that metabolized the waste out of the water. A clarifier then worked to settle out the solids. Afterwards, Ecological Fluidized Beds, developed by Ocean Arks International, provided the final polishing, nitrification, and suspended solid digestion. The site served as an educational center for local schools and resembled a local garden center more

than a waste treatment facility.

Sewage flows to a greenhouse with two treatment trains, each with five aerobic reactors, a clarifier and three Ecological Fluidized Beds. The open aerobic reactors had aerators, planted with a variety of aquatic plant species in floating plant racks (over 350 species were tested, including flowering plants). The air and plants provide an environment that hosts a variety of organisms that digest the nutrients and pollutants in the wastewater. Biochemical Oxygen Demand (BOD), Total Suspended Solids (TSS) and ammonia nitrate were reduced in this stage of treatment. A clarifier follows the open aerobic reactors to settle out the solids.

Ecological Fluidized Beds (EFBs) in each train follow the clarifier for final polishing. Thus, the EFBs operate aerobically and provide the final polishing, nitrification, and suspended solids digestion. Designed to achieve stable nutrient removal, this Eco-Machine was cost competitive, alternative treatment to a conventional system. With its aesthetic beauty and lack of offensive odor, this system is compatible with a residential environment. The South Burlington Eco-Machine was also used as a teaching tool for many different schools and universities in the region. Elementary through High School grade science students toured the facility for first hand lessons on ecology, engineering, and environmental stewardship. University students were given more involved assignments in the intricacies of each ecosystem, and research applications. The facility provided many students the opportunity to work in and around this innovative system.